Osmotic drug delivery system

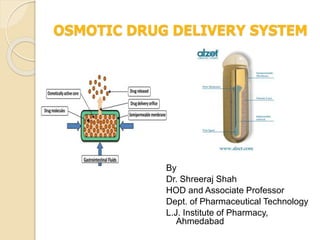

- 1. OSMOTIC DRUG DELIVERY SYSTEM By Dr. Shreeraj Shah HOD and Associate Professor Dept. of Pharmaceutical Technology L.J. Institute of Pharmacy, Ahmedabad

- 2. LIST OF CONTENTS INTRODUCTION ADVANTAGES OF OSMOTIC DRUG DELIVERY SYSTEM DISADVANTAGES OF OSMOTIC DRUG DELIVERY SYSTEM PRINCIPLE OF OSMOSIS BASIC COMPONENTS OF OSMOTIC PUMP FACTORS AFFECTING RELEASE OF MEDICAMENT FROM OSMOTIC DDS OSMOTIC PUMPS FIRST OSMOTIC PUMP (THREE CHAMBER ROSE-NELSON OSMOTIC PUMP) ELEMENTARY OSMOTIC PUMP (EOP) CONTROLLED PORSITY OSMOTIC PUMPS (CPOP) OSMOTIC BURSTING OSMOTIC PUMP (OBOP) PUSH PULL OSMOTIC PUMP (PPOP) SANDWICHED OSMOTIC TABLETS (SOTS) OROS-CT L-OROS IMPLANTABLE OSMOTIC PUMPS ALZET® DUROS®

- 3. PULSATILE DRUG DELIVERY OSMOTIC PUMPS DELAYED DELIVERY OSMOTIC DEVICES EVALATION OF OSMOTIC TABLETS IN VITRO EVALUATION MARKET PRODUCTS REFERENCES

- 4. INTRODUCTION Osmotic drug delivery uses the osmotic pressure of drug or other solutes (osmogens or osmagents) for controlled delivery of drugs. Osmotic drug delivery has come a long way since Australian physiologists Rose and Nelson developed an implantable pump in 1955.

- 5. ADVANTAGES OF OSMOTIC DRUG DELIVERY SYSTEM The delivery rate of zero-order (which is most desirable) is achievable with osmotic systems. Delivery may be delayed or pulsed, if desired. For oral osmotic systems, drug release is independent of gastric pH and hydrodynamic conditions which is mainly attributed to the unique properties of semipermeable membrane (SPM) employed in coating of osmotic formulations.

- 6. ADVANTAGES Higher release rates are possible with osmotic systems compared with conventional diffusion-controlled drug delivery systems. The release rate of osmotic systems is highly predictable and can be programmed by modulating the release control parameters. A high degree of in vivo–in vitro correlation (IVIVC) is obtained in osmotic systems because the factors that are responsible for causing differences in release profile in vitro and in vivo (e.g., agitation, variable pH) affect these systems to a much lesser extent.

- 7. ADVANTAGES The release from osmotic systems is minimally affected by the presence of food in the gastrointestinal tract (GIT). This advantage is attributed to design of osmotic systems. Environmental contents do not gain access to the drug until the drug has been delivered out of the device. Production scale up is easy.

- 8. Expensive Chance of toxicity due to dose dumping Rapid development of tolerance Hypersensitivity reaction may occur Integrity and consistency are difficult Release of drug depends on : - size of hole/aperture - surface area - thickness and composition of membrane 8/6 0 DISADVANTAGES OF OSMOTIC DRUG DELIVERY SYSTEM

- 9. PRINCIPLE OF OSMOSIS Osmosis refers to the process of movement of solvent from lower concentration of solute towards higher concentration of solute across a semi permeable membrane. Abbe Nollet first reported osmotic effect in 1748, but Pfeffer in 1877 had been the pioneer of quantitative measurement of osmotic effect. Pfeffer measured the effect by utilizing a membrane which is selectively permeable to water but impermeable to sugar. The membrane separated sugar solution from pure water. Pfeffer observed a flow of water into the sugar solution that was halted when a pressure p was applied to the sugar solution. Pfeffer postulated that this pressure, the osmotic pressure π of the sugar solution is proportional to the solution concentration and absolute temperature. Van’t Hoff established the analogy between the Pfeffer results and the ideal gas laws by the expression π = n2RT----------------------(1) Where n2 represents the molar concentration of sugar (or other solute) in the solution, R depicts the gas constant, and T the absolute temperatue. This equation holds true for perfect semipermeable membranes and low solute concentrations.

- 10. Another method of obtaining a good approximation of osmotic pressure is by utilizing vapour pressure measurements and by using expression: π = RT ln (Po/P)/v -------- (2) Where Po represents the vapour pressure of the pure solvent, P is the vapour pressure of the solution and v is the molar volume of the solvent. As vapour pressure can be measured with less effort than osmotic pressure this expression is frequently used.

- 11. Osmotic pressure for soluble solutes is extremely high. This high osmotic pressure is responsible for high water flow across semipermeable membrane. The rate of water flow dictated by osmotic pressure can be given by following equation, dV/dt = A θ Δπ/l ----------------------- (3) Where dV/dt represents the water flow across the membrane area A and thickness l with permeability θ. Δπ depicts the difference in osmotic pressure between the two solutions on either side of the membrane. NOTE- This equation is strictly applicable for perfect semipermeable membrane, which is completely impermeable to solutes.

- 12. Schematic representation of the basic model of osmotic pressure powered drug delivery systems Vs Vd PUMP HOUSING DELIVERY ORIFICE MOVABLE PARTITION SEMIPERMEABLE MEMBRANE Vs is volume of osmotic agent compartment Vd is volume of drug compartment

- 13. When a single osmotic driving agent is used, the pumping rate of the osmotic device of (volume per unit time) is defined by Q/t = Pw Sm [γm (πs- πe)-(ΔPd+ΔPc)] ------------ (4) Pw is permeability of semi permeable membrane to water; Sm is effective surface area of the membrane; γm is osmotic reflection coefficient of the membrane; πs and πe are the osmotic pressure of saturated solution of osmotic driving agent and of the environment where device is located, respectively; ΔPd is elevation of internal pressure generated in the drug formulation compartment as the result of water influx into osmotic agent compartment; ΔPc is pressure required to deform drug formulation compartment inward. If the net osmotic pressure gradient [γm (πs- πe)] is constant and the hydrostatic pressure (ΔPd+ΔPc) is negligibly small, equation (4) can be simplified to: Q/t = Pw Sm (πs- πe) -------------- (5)

- 14. And a zero order rate of drug release from osmotic device can be achieved if following conditions are met: The amount of osmotic driving agent used is sufficient to maintain a saturated solution in the osmotic agent compartment i.e. πs is constant. The environmental osmotic activity is either constant or negligibly small i.e. (πs- πe) ≈ constant. The osmotic reflection coefficient is constant and very close to unity i.e. γm≈1. That means ideal semi permeable membrane, selectively permeable to water but not to osmotic drug agent, should be used. A sufficiently large delivery orifice and a highly deformable partition should be used. So, ΔPd =ΔPc≈0.

- 15. BASIC COMPONENTS OF OSMOTIC PUMP DRUG Drug itself may act as an osmogen and shows good aqueous solubility (e.g., potassium chloride pumps). But if the drug does not possess an osmogenic property, osmogenic salt and other sugars can be incorporated in the formulation.

- 16. OSMOGEN / OSMAGENT / OSMOTIC DRIVING AGENT For the selection of osmogen, the two most critical properties to be considered are osmotic activity and aqueous solubility. Osmotic agents are classified as, Inorganic water soluble osmogens: Magnesium sulphate, Sodium chloride, Sodium sulpahte, Potassium chloride, Sodium bicarbonate etc. Organic polymeric osmogens: Na CMC, HPMC, HEMC, etc. Organic water soluble osmogens: Sorbitol, Mannitol,etc.

- 18. SEMIPERMEABLE MEMBRANE Semipermeable membrane must possess certain performance criteria: It must have sufficient wet strength and water permeability. It should be selectively permeable to water and biocompatible. Cellulose acetate is a commonly employed semipermeable membrane for the preparation of osmotic pumps. Some other polymers such as agar acetate, amylose triacetate, betaglucan acetate, poly (vinyl methyl) ether copolymers, poly (orthoesters), poly acetals, poly (glycolic acid) and poly (lactic acid) derivatives. The unique feature of semipermeable membrane utilized for an osmotic pump is that it permits only the passage of water into the unit, thereby effectively isolating the dissolution process from the gut environment.

- 19. HYDROPHILIC AND HYDROBHOBIC POLYMERS These polymers are used in the formulation development of osmotic systems containing matrix core. The selection of polymer is based on the solubility of drug as well as the amount and rate of drug to be released from the pump. The highly water soluble compounds can be co-entrapped in hydrophobic matrices and moderately water soluble compounds can be co-entrapped in hydrophilic matrices to obtain more controlled release. Examples of hydrophilic polymers are Hydroxy ethyl cellulose, carboxy methyl cellulose, hydroxyl propyl methyl cellulose, etc. Examples of hydrophobic polymers are ethyl cellulose, wax materials, etc.

- 20. WICKING AGENTS It is defined as a material with the ability to draw water into the porous network of a delivery device. The function of the wicking agent is to draw water to surfaces inside the core of the tablet, thereby creating channels or a network of increased surface area. Examples: colloidon silicon dioxide, kaolin, titanium dioxide, alumina, niacinamide,sodium lauryl sulphate (SLS), low molecular weight polyvinyl pyrrolidone (PVP), bentonite, magnesium aluminium silicate, polyester and polyethylene,etc.

- 21. SOLUBILIZING AGENTS Non swellable solubilizing agents are classified into three groups: Agents that inhibits crystal formation of the drugs or otherwise act by complexation of drug (e.g., PVP, PEG, and cyclodextrins) A high HLB micelle forming surfactant, particularly anionic surfactants (e.g., Tween 20, 60, 80, poly oxy ethylene or polyethylene containing surfactants and other long chain anionic surfactants such as SLS). Citrate esters and their combinations with anionic surfactants (e.g., alkyl esters particularly triethyl citrate)

- 22. SURFACTANTS They are added to wall forming agents. The surfactants act by regulating the surface energy of materials to improve their blending in to the composite and maintain their integrity in the environment of use during the drug release period. Examples: polyoxyethylenated glyceryl recinoleate, polyoxyethylenated castor oil having ethylene oxide, glyceryl laurates, etc.

- 23. COATING SOLVENTS Solvents suitable for making polymeric solution that is used for manufacturing the wall of the osmotic device include inert inorganic and organic solvents. Examples: methylene chloride, acetone, methanol, ethanol, isopropyl alcohol, ethyl acetate, cyclohexane, etc.

- 24. PLASTICIZERS Permeability of membranes can be increased by adding plasticizer, which increases the water diffusion coefficient. Examples: dialkyl pthalates, trioctyl phosphates, alkyl adipates, triethyl citrate and other citrates, propionates, glycolates, glycerolates, myristates, benzoates, sulphonamides and halogenated phenyls.

- 25. FLUX REGULATORS Flux regulating agents or flux enhancing agent or flux decreasing agent are added to the wall forming material; it assist in regulating the fluid permeability through membrane. Poly hydric alcohols such as poly alkylene glycols and low molecular weight glycols such as poly propylene, poly butylene and poly amylene,etc. can be added as flux regulators.

- 26. PORE FORMING AGENTS These agents are particularly used in the pumps developed for poorly water soluble drug and in the development of controlled porosity or multiparticulate osmotic pumps. The pore formers can be inorganic or organic and solid or liquid in nature. For example Alkaline metal salts such as sodium chloride, sodium bromide, potassium chloride, etc. Alkaline earth metals such as calcium chloride and calcium nitrate Carbohydrates such as glucose, fructose, mannose,etc.

- 27. Factors affecting release of medicament from Osmotic DDS A. Solubility B. Osmotic pressure C. Delivery orifice D. Membrane type

- 28. A. solubility • Solubility of drug is one of the most important factors since kinetic of osmotic release is directly related to the drug solubility. • The fraction of a drug release with zero order kinetic is given by • Where F (z): fraction release by zero order S: drug solubility in g / cm 3 P: density of core tablet. • Drug with density of unity and solubility less than 0.05 g / cm3 would release greater than or equals to 95 % by zero order kinetics • Drug with density > 0.3 g / cm3 solubility would demonstrate with higher release rate > 70 % by zero order. • Both highly soluble and poorly soluble drugs are not good candidates for osmotic drug delivery F (z) = 1 – S P

- 29. B Osmotic pressure The next release-controlling factor that must be optimized is the osmotic pressure gradient between inside the compartment and the external environment The simplest and most predictable way to achieve a constant osmotic pressure is to maintain a saturated solution of osmotic agent in the compartment The release rate of a drug from an osmotic system is directly proportional to the osmotic pressure of the core formulation 29/ 60

- 30. C. Delivery orifice To achieve an optimal zero order delivery profile, the cross sectional area of the orifice must be smaller than a maximum size to minimize drug delivery by diffusion through the orifice Furthermore, the area must be sufficiently large, above a minimum size to minimize hydrostatic pressure build up in the system The typical orifice size in osmotic pumps ranges from 600µ to 1 mm. 30/ 60

- 31. Methods to create a delivery orifice in the osmotic tablet coating Mechanical drill Laser drilling : CO2 laser beam Use of modified punches Use of pore formers : used in controlled porosity osmotic pump Ex. of pore formers: dimethyl sulfone, nicotinamide, saccharides, amino acids, sorbitol, pentaerythritol, mannitol, organic aliphatic, and aromatic acids, including diols and polyols 31/ 60

- 32. D. Membrane type Type and nature of polymer polymer that is permeable to water but impermeable to solute can be selected Ex. cellulose esters such as cellulose acetate, cellulose diacetate, cellulose triacetate, cellulose propionate, cellulose acetate butyrate Membrane thickness release rate from osmotic systems is inversely proportional to membrane thickness Type and amount of plasticizer Chlorpromazine release from CPOP was found to increase with decreasing amounts of TEC (triethyl citrate) 32/ 60

- 33. Classification of Osmotic Pumps

- 34. Single osmotic pump Elementary osmotic pump (EOP) Controlled porosity osmotic pump (CPOP) Osmotic bursting osmotic pump Multi-chamber osmotic pump Push pull osmotic pump (PPOP) Sandwich osmotic tablets (SOTS) Oral osmotic capsules OROS- CT L- OROS Pelleted delayed release Asymmetric membrane capsule Telescopic capsule for delayed release Implantable osmotic system DUROS osmotic pump ALZET osmotic pump Oral osmotic tablet

- 35. Type of Implantable Osmotic Pumps

- 36. FIRST OSMOTIC PUMP (THREE CHAMBER ROSE-NELSON OSMOTIC PUMP) Drug Chamber Elastic Diaphragm Salt Chamber Rigid Semi permeable membrane Water Chamber Delivery orifice Water to be loaded prior to use was the drawback of rose nelson osmotic pump

- 37. ELEMENTARY OSMOTIC PUMP (EOP) Rose Nelson pump was further simplified in the form of elementary osmotic pump (by Theeuwes,1975) which made osmotic delivery as a major method of achieving controlled drug release.

- 38. ELEMENTARY OSMOTIC PUMP (EOP) Core containing agent Delivery Orifice Semi permeable membrane It essentially contains an active agent having a suitable osmotic pressure. It is fabricated as a tablet coated with semi permeable membrane, usually cellulose acetate. A small orifice is drilled through the membrane coating. This pump eliminates the separate salt chamber unlike others. When this coated tablet is exposed to an aqueous environment, the osmotic pressure of the soluble drug inside the tablet draws water through the semi permeable coating and a saturated aqueous solution of drug is formed inside the device. The membrane is non-extensible and the increase in volume due to imbibition of water raises the hydrostatic pressure inside the tablet, eventually leading to flow of saturated solution of active agent out of the device through the small orifice. The process continues at a constant rate till the entire solid drug inside the tablet is eliminated leaving only solution filled shell. This residual dissolved drug is delivered at a slower rate to attain equilibrium between external and internal drug solution.

- 39. LIMITATION OF EOP Generally in osmotic pumps the semi permeable membrane should be 200-300μm thick to withstand pressure with in the device. These thick coatings lower the water permeation rate, particularly for moderate and poorly soluble drugs. In general we can predict that these thick coating devices are suitable for highly water soluble drugs. This problem can be overcome by using coating materials with high water permeabilities. For example, addition of plasticizers and water soluble additive to the cellulose acetate membranes, which increased the permeability of membrane up to ten fold.

- 40. Controlled Porosity Osmotic Pump (CPOP) The delivery orifice is formed by incorporation of a leachable water-soluble component in the coating material Drug release from the whole surface of device rather than from a single hole which may reduce stomach irritation problem

- 41. The semi permeable coating membrane contains water-soluble pore forming agents like NaCl, KCl, and Urea. Such formed pores becomes permeable for both water and solutes. The release rate from these types of systems has been reported to be dependent on : ◦ the coating thickness (20-500 𝜇m) ◦ level of soluble components in the coating solubility of the drug in the tablet core ◦ osmotic pressure difference across the membrane (8-500 atm) but independent of the pH and agitation of the release media Ex. Chitosan-based controlled porosity osmotic pump (Citric Acid as pore forming) for colon-specific delivery system: screening of formulation variables and in vitro investigation : microbially triggered colon-targeted osmotic pump (MTCT- OP) The gelable property at acid condition and colon-specific biodegradation of chitosan

- 42. SPECIFICATIONS FOR CONTROLLED POROSITY OSMOTIC PUMPS Materials Specifications Plasticizers and flux regulating agents 0 to 50, preferably 0.001 to 50 parts per 100 parts of wall material Surfactants 0 to 40, preferably 0.001 to 40 parts per 100 parts of wall material Wall Thickness 1 to 1000, preferably 20 to 500μm Micro porous nature 5 to 95% pores between 10Å to 100μm Pore forming additives 0.1 to 60%, preferably 0.1 to 50%, by weight, based on the total weight of pore forming additive and polymer pH insensitive pore forming additive (solid or liquid) preferably 0.1 to 40% by weight

- 43. SPECIFICATIONS FOR CORE OF CONTROLLED POROSITY OSMOTIC PUMPS Property Specifications Core loading (size) 0.05ng to 5g or more (include dosage forms for humans and animals) Osmotic pressure developed by a solution of core 8 to 500atm typically, with commonly encountered water soluble drugs and excipients Core solubility To get continuous, uniform release of 90% or greater of the initially loaded core mass solubility, S, to the core mass density, ρ, that is S/ρ, must be 0.1 or lower. Typically this occurs when 10% of the initially loaded core mass saturates a volume of external fluid equal to the total volume of the initial core mass

- 44. Osmotic bursting osmotic pump Core: API ± osmogents Coat: Semi permeable membrane without delivery orifice When placed in aqueous environment, water is imbibed and hydraulic pressure is built up inside the system, then wall ruptures and the contents are released. It is used for pulsated release. 44

- 45. Multichamber osmotic pump Push Pull Osmotic System (PPOP) They contain two or three compartment separated by elastic diaphragm Upper compartment contain drug with or without osmogen (drug compartment nearly 60 – 80 %) and lower compartment (Push compartment) contain Osmogen at 20 – 40 %. It is a bilayer tablet coated with semi permeable membrane. Example Procardia XL for Nifedipine

- 48. Sandwiched Osmotic tablets (SOTS) It is composed of polymeric push layer sandwiched between two drug layers with two delivery orifices. When placed in the aqueous environment the middle push layer containing the swelling agents, swells and the drug is released from the delivery orifices. Advantage : the drug is released from the two orifices situated on opposite sides of the tablet 48

- 50. A more sophisticated version of this device consists of two rigid chambers, one contains biologically inert osmotic agent such as sugar or NaCl, and the second chamber contains the drug. When exposed to aqueous environment, water is drawn into both chambers across the semi permeable membrane. The solution of osmotic agent then passes into the drug chamber through the connecting hole where it mixes with the drug solution before escaping through the micro porous membrane that forms part of the wall around the drug chamber. Relatively insoluble drugs can be delivered using this device. Osmotic agent containing chamber Semi permeable membrane orifice Drug containing chamber Microporous membrane

- 51. OROS Capsules OROS- CT It is developed by Alza co-operation. It is used as a once or twice a day formulation for targeted delivery of drugs to the colon It consist of an enteric coat, SPM & core. Core consist of two compartments - one compartment consist of drug near to orifice. -Second compartment consist of osmopolymer The OROS-CT can be a single osmotic agent or it can be comprise of as many as five to six push pull osmotic unit filled in a hard gelatin capsule.

- 52. Cross-sectional diagram of OROS CT delivery system

- 53. L-OROS Liquid OROS controlled release systems are designed to continuous deliver drugs as liquid formulations. A liquid formulation is used for delivering insoluble drugs and macromolecules. Such molecules require external liquid components to assist in solubilization, dispersion, protection from enzymatic degradation and promotion of gastrointestinal absorption. It combines the benefits of extended-release with high bioavailability. These are of two types -: - L-OROS Soft cap - L-OROS Hard cap

- 54. L-OROS Soft cap The liquid drug formulation is present in a soft gelatin capsule, which is surrounded with the barrier layer, the osmotic layer, and semi permeable membrane. A delivery orifice is formed through these three layers. When the system is in contact with the aqueous environment, water is imbibed & results in the development of osmotic pressure inside the system forcing the liquid formulation to break through the hydrated gelatin capsule shell at the delivery orifice.

- 55. 55 Cross-sectional diagram of L-OROS (Soft cap) delivery system before and during operation

- 56. L-OROS Hard Cap Another type of L-OROS system consists of a hard gelatin capsule containing a liquid drug layer, a barrier layer and a push layer surrounded by a semipermeable membrane. The L-OROS hardcap system was designed to accommodate more viscous suspensions with higher drug loading than would be possible using softcap design. Rate controlling membrane Push layer Inner Capsule Delivery orifice Inner Compartment Barrier layer

- 57. Implantable osmotic pump Implantable systems further classified as-: 1. For experimental use 2. For human use For experimental use -: ALZET® It is a miniature, implantable osmotic pumps for laboratory animals. The pump are used to deliver homogenous solutions or suspensions continuously at a controlled rate for extended period. It consist of Drug reservoir, osmotic sleeve & semipermeable membrane.

- 58. ALZET® osmotic pump 58 Design: Empty reservoir within the core of the pump is filled with the drug or hormone solution to be delivered and is surrounded by salt chamber with impermeable layer between them. Mechanism: Water enters into the salt chamber through semipermeable membrane and causes compression of flexible reservoir and delivery of drug solution. Application: To deliver drugs, hormones, and other test agents continuously at controlled rates from one day to six weeks.

- 60. ALZET OSMOTIC PUMPADVANTAGES Ensure around-the-clock exposure to test agents at predictable levels. Permit continuous administration of short half-life proteins and peptides. Convenient method for chronic dosing of laboratory animals. Minimize unwanted experimental variables and ensure reproducible, consistent results. Eliminate the need for nighttime or weekend dosing. Reduce handling and stress to laboratory animals. Small enough for use in mice or very young rats. Allow for targeted delivery of agents to virtually any tissue. Cost-effective research tool

- 61. ALZET® Osmotic Pumps are available in three sizes

- 62. DUROS® osmotic pump 62 Design : ◦ Implantable drug-dispensing osmotic pump, shaped as a small rod with titanium housing. Mechanism : Through osmosis, water from the body is slowly drawn through the semi-permeable membrane into the pump by osmotic agent residing in the engine compartment, which expands the osmotic agent and displaces a piston to dispense small amounts of drug formulation from the drug reservoir through the orifice. Application: Systemic or site-specific administration of a drug

- 63. • Affecting factors – Compositions of osmotic agent – Thickness of semipermeable membrane – Surface area

- 64. DUROS® DUROS® implants are designed to bring the benefit of continuous therapy for up to one year. The non-biodegradable, osmotically driven system is intended to enable delivery of small drugs, peptides, proteins, DNA and other bioactive macromolecules for systemic or tissue-specific therapy. Viadur® (leuprolide acetate implant), the first marketed product to incorporate DUROS®, is indicated for the palliative treatment of advanced prostate cancer. ADVANTAGES Can deliver highly concentrated and viscous formulations. Improved patient compliance Titanium protects the drug from enzymatic degradation. The system can be engineered to deliver a drug at a desired dosing rate with high degree of precision.

- 65. PULSATILE DRUG DELIVERY Delivering a drug in one or more pulses is sometimes beneficial, from the required pharmacological action point of view. Mechanical and drug solubility– modifying techniques have been implemented to achieve the pulsed delivery of drugs with an osmotic system.

- 66. DELAYED-DELIVERY OSMOTIC DEVICES Because of their semipermeable walls, osmotic devices inherently show a lag time before drug delivery begins. Although this characteristic is usually cited as a disadvantage, it can be used advantageously. The delayed release of certain drugs (e.g., drugs for early morning asthma or arthritis) may be beneficial. The following slides describes other means to further delay drug release.

- 67. Evaluation of Osmotic tablet Pre-compression parameters Post compression parameters Pore diameter Coating thickness In Vitro drug release Zero order release kinetics First order release kinetics Effect of Osmotic pressure Effect of pH on drug release Effect of agitation

- 68. IN VITRO EVALUATION The in vitro release of drugs from oral osmotic systems has been evaluated by the conventional USP paddle and basket type apparatus. The dissolution medium is generally distilled water as well as simulated gastric fluid (for first 2-4 h) and intestinal fluids (for subsequent hours) have been used. The standard specifications, which are followed for the oral controlled drug delivery systems are equivalently applicable for oral osmotic pumps. In vivo evaluation of oral osmotic systems has been carried out mostly in dogs. Monkeys can also be used but in most of the studies the dogs are preferred.

- 72. Verma R., Mishra B. and Garg S., Osmotically controlled oral drug delivery; Drug Development and Industrial Pharmacy, 26(7), 695-708 (2000) Kaushal M. and Garg S., “ An Update on Osmotic Drug Delivery Patents”; Pharmaceutical Technology, August 2003 38-45. Theeuwes F.,”Elementary Osmotic Pump”, Journal of Pharmaceutical Science;64(12):1987-1991(1975). Theeuwes F., Journal of Pharmaceutical Science;72:253(1983). Chein Y., Novel Drug Delivery Systems:398-407

- 73. Wong P.,Gupta S. and Stewart B. Modified Release Drug Delivery Technology: Osmotically controlled tablets:101-114 Fara J. and and Ray N.; Drug Delivery Devices, Fundamentals and Applications, :137-175 Santus G., and Baker R., “Osmotic Drug Delivery: A Review of the Patent Literature,” J. Controlled Release 35, 1–21 (1995). Swarbrick J. and Boylan J, “Encyclopedia of Pharmaceutical Technology”, Vol. 3: 297-300 www.fda.gov/ohrms/dockets/ac/04/slides/2004078S1_13_Kha n.ppt cooklab.rutgers.edu/Intro_Lect_webct.ppt