Formulas kiln

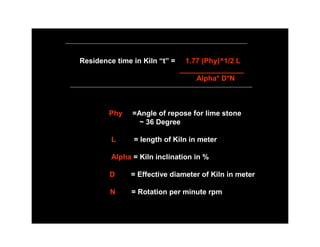

- 1. Residence time in Kiln “t” = 1.77 (Phy)^1/2 L ________________ Alpha* D*N Phy =Angle of repose for lime stone ~ 36 Degree L = length of Kiln in meter Alpha = Kiln inclination in % D = Effective diameter of Kiln in meter N = Rotation per minute rpm

- 2. Kiln Kiln Inlet Outlet A B C D E Preheater Zone = 1 min A 7.5m/sec Mat velo Max Precalcination Zone = 2 min B t = 20 -28 = Minutes Calcination Zone = 10-12 min C Burning Zone = 6 – 8 min D 4.5m/sec Cooling Zone = 2 min F Mat Velo Min

- 3. CLINKERISATION 12 CaO 3Cao.SiO2 (C3S) Lime stone Alite 2 SiO2 2CaO SiO2 (C2S) Silica oxide Belite 1450*C 2 Al2O3 3 CaOAl2O3 (C3A) Aluminium oxide Tricalcium Aluminate Fe2O3 4CaO.Al2O3.Fe2O3 (C4AF) Iron oxide Tetra Calcium Alumino Ferrite

- 4. LIME SATURATION FACTOR 100* CaO LSF = (2.8 SiO2 + 1.18 Al2O3 + 0.65 Fe2O3) 0.66 > LSF < 1.2 = = AR = > 0.64

- 5. SILICA RATIO SiO2 SR = (Al2O3 + Fe2O3) 2.2 > SR < 2.6 = =

- 6. ALUMINA RATIO Al2O3 AR = Fe2O3 1.5 > AR < 2.5 = = AR < 1.5 IS CALLED FERROCEMENTS AR = 0.637 IS CALLED FERRARI CEMENT

- 7. CALORIFIC VALUE OF COAL LHV = HHV – 50.1H – 5.6 M – 0.191O LHV = LOW HEATING VALUE Kcal /Kg HHV = HIGH HEATING VALUE Kcal /Kg M = % MOISTURE H = % HYDROGEN O = % OXYGEN KCal / Kg x 4.187 x 10^(-3) = MJ/Kg ultimate analysis KCal / Kg x 1.8 = Btu / lb

- 8. COAL USED IN CEMENT INDUSTRY • LHV = 6500 – 7000 Kcal / Kg • ASH = 12~15 % • VOLATILE MATERIAL = 18~ 22 % • MOISTURE = UP TO 12 %

- 9. D =Diameter in Meter L = Length in meter WEIGHT OF CYLINDRICAL( kiln) SHELL = W W = Pi x (L) x (D) x thk (mm) x 7.85 Metric Tons

- 10. THERMAL EXPANSION OF SHELL Skin Temperature Diagram A = Alpha x TxL L= Length of (Kiln) Shell =L1 + L2 Alpha for steel (coefficient of linear expansion = 1.2x 10^ (-5) mm per Meter T= dT =( Average temp – Ambient temp) Degre centigrade L1 L2 A1= (T2a+T1)/2 - T X L1 T2bb A1= (T2b+T1)/2 - T X L2 T1 Ambient temp = T T2a A = A1 +A2

- 11. IMPOTANT PARAMETERS KILN SPECIFIC VOLUME LOADING = TPD/ m3 or Specific Kiln capacity ~ 2.3 t / m3 at Kiln circumferential speed = 50 cm / sec KILN SPECIFIC THERMAL LOADING = Kcal / m2.hr Specific Kiln thermal loading Qp = 1.4 x 10 ^ 6 x D Kcal / m2. hr Qp should not exceed 3.46 x 10^6 Kcal/m^2.hr COOLER SPECIFIC LOADING or Specific Cooler Capacity = TPD/ m2 = 38 -43 metric ton of clinker per m^2 .24 hr KILN % FILLING = 04 % Min - 16% Max

- 12. KILN CAPACITY ASSESMENT •Capacity of ID fan. •Preheater cyclone design. •Proclaimed Design & Volume. •Kiln inclination & Volume. •Kiln % filling, Specific volume loading &.Thermal loading. •Kiln Drive capacity. •System Design, Ducts, GCT, fan position & ESP.

- 13. For Gears: Pitch Diameter = Module x No. of Teeth Blank Diameter = Module x (No of Teeth+2) For Airslide Cloth • Fabric Polyester 100%. • Min=140*C & Max = 260*C. • Permeability = 400m3/hr-m2 or 6m3/min-m2. at 80mbar • Tensile strength : WEFT = 1200 Kg/cm2 : WARP = 600 Kg/cm2 • Air Required = 2.5-3.0(Closed type), (2 Cone silo Bins),(1.5Open Type)

- 14. PH fan-1 Twin cyclones PH fan-2 Twin cyclones IA IB II III IV Riser Duct V KILN STRING VI V 950*C T.A.Duct SLC PYRO STRING KILN I Girth gear II III

- 15. CEMENT MILL FORMULAS MILL CRITICAL VELOCITY = 76 / (D)^1/2 MILL ACTUAL VELOCITY = 32 / (D)^1/2

- 16. D Theta’ Mill charging: Theta H H = 0.16D MILL CROSS SECTION Dynamic Angle of Repose = 35 degree 20 minutes with Horizontal (Theta ) OR Dynamic Angle of Repose = 54 degree 40 minutes with Vertical (Theta )’

- 17. GRINDING MEDIA LOAD “ G” G = gm.Sy.Pi. (R)^2.L 4 Constants: Sy = specific gravity of G = 4620(R)^2.L ball 7.8-7.9 Ton / m3 gm = Bulk density of charge TAGGARTS FORMULA 4.5 Ton / m3 . Pi = 22/7 or 3.14

- 18. POWER CONSUMPTION OF MILL = P L= G/D=A-C 2. B-A P= 12G SEPARATOR B%fines/D A %fines/F Seperator efficiency A % fines of separator feed s B % fines of Tailings/Reject C%fine/G C % fines of finished Product F TPH of separator feed D TPH of Tailings/Reject G TPH of finished Product Ball Mill 1. n = C (A-B) 3. A(C-B)) F = L(1+D)

- 19. L/D=3 Two Compartment Mill L / D = 4.5 Three Compartment Mill I – Chamber Drag Peb Liners Carman Lining Classifying Slegton – Liners Magotteaux Lining Lining FLS Lining

- 20. Important Conversions 1 Barrel = 42 Gallons = 159 litres = 5.615 Cuft 1 Kcal = 4.187 J KCal / Kg x 1.8 = Btu / lb Characteristic OPC-43(IS8112) OPC-43(IS12269) PPC- (IS1489)Part-1 Blaine 225 225 300 3 Days(MPa) 23 27 16 7 Days 33 37 22 28 Days 43 53 33

- 21. L H 70 * L=H/2 Length of Dip Tube = ½ Gas inlet height Single Stream

- 25. TOP VIEW GASCONDITIONING TOWER SPRAY SIDE VIEW

- 28. Kiln Data : 4.4 meter Diameter x 60 meter length Inclination = 3.5% Shell thicknesses = 25 mm , 28 mm , 35 mm , 65 mm Kiln speed = 3.5 to 5.25 RPM Preheater : Type : 6440 / PR 7044 VI Stage Desc Kiln string Pyro string I Cyclone Twin 4000 m 4400 m (Diameter) 6400 m 7000 m Dip tube 2000 m 2200 m (Diameter) 3200 m 3500 m

- 29. Girth Gear : Module = 39 No of Teeth = 148 Material of construction = CS 640 (Normalized Cast Steel) Dimensions = 550 mm (width) Pinion : Module = 39 No of Teeth = 28 Material of construction = 30 Cr Ni Mo V8 (Normalized CastSteel) Dimensions = 600 mm (width)

- 30. Tyre Assemblies three no’s : Material of construction = GS 24 Mn 5 (Normalized Cast Steel) Dimensions = 5620 OD x 4581 ID x 775 (width) Main Drive Supporting Rollers Assemblies three no’s : Material of construction = CS 640 (Normalized Cast Steel) Dimensions = 5620 OD x 4581 ID x 775 (width) Tyre Kiln Supporting Roller Shell Girth Gear Pinion

- 31. Kiln Main Drive : Gear box = SDN 800 Ratio = 54.35:1 RWN-500 Motor KW = 710 Aux G.B SDA 250 54.35: 1 Input RPM = 100 - 1000 Motor 30 KW ; 1500 RPM Motor G.B G.B Motor RWB-178 Pinion Kiln Axis Concord Alingnomatic Geared Coupling G.G

- 34. MID KILN FEEDING

- 36. Degree Of Kiln filling & Kiln Cross Sectional loading: % of Filling or Area of this segment (A1) = Kilns Degree Area of cross section of Kiln (A) Theta Centric Angle Theta % of Kiln (Degree) filling 110 15.65 105 13.75 100 12.1 Segment 95 10.7 r = radius inside lining 90 9.09 85 7.75 r^2 A1 = O – Sin O 80 6.52 2 75 5.42 70 4.5 A = II r^2

- 37. Rotary Kiln Slope versus Load Theta 4.5 4.0 3.5 3.0 2.0 % 9 10 11 12 13 Note : In practical Kiln operation the kiln load should not exceed 13%,since higher Kiln loads impair the heat tranfer Thumb rule by Bohman Material velocity in kiln % Kiln Kiln diameter 1). Burning Zone = 4.5 mm / sec Lowest Slope (m) 5 up to 2.8 m 4 3 m to 3.4 m 2). Calcining Zone = 7.5 mm / sec Max 3 > 3.4 m

- 38. Rotary Kiln power input calculation : W x bd x td x N x F x 0.0000092 1 H.P = rd W = Total vertical load on all roller shaft bearing,lb bd = roller shaft bearing diameter , inches Note : This is Frictional rd = roller diameter , inches 1 Horse Power td = tire or riding rind diameter , inches N = rpm of Kiln shell P = Coefficient or friction of roller bearings , 0.018 for oil lub bearings & 0.06 for grease lub bearings

- 39. This is Load Horse 2 Horse Power H.P = (D x Sin O) ^3 x N x L x K 2 D = Kiln dia .inside lining , ft Sin O = read from diagram depending on %Load N = rpm of Kiln shell L = length of kiln in ft K = 0.00076 Total power = 1 + 2

- 40. Cement Monthly - Edelweiss From: Arun Shourie [mailto:Arun.Shourie@edelcap.com] Arun Shourie Relation Manager - Insurance Dir: +91 (22) 4086 3835 / +91 99200 29366

- 41. Burner pipe centering location and alignment Burner Pipe Location 40* L v H d D

- 42. = V Z Cos O D–a–b X K% = Z 2 H = Z Sine O Kiln Diameter = D Kiln lining thickness = a Kiln Coating thickness = b Angle of Repose of kiln load = O = 40* say Kiln Load = K % Value from table below Depth of bed in Kiln = Y % To be measured Kiln load = K % 5 6 7 8 9 10 11 12 13 14 15 Depth of material bed in Kiln = Y % 9.75 11 12.2 13.4 14.5 15.6 16.7 17.7 1.8.8 19.8 21

- 43. Standard Coal Factor : SCF To determine the approximate combustion air needed to burn a given unit wt of coal, formula given below can be used when no ultimate analysis is available. The combustion air requirement include here 5% of excess air 100 - a B = SCF 100 7000 Kg of Air = 10.478 SCF Kg of Coal a = % Moisture in coal ( as fired ) B = Heat value of coal ( Kcal / kg as fired )

- 44. % Loading of Kiln : Theoretical Flame Temperature fuel oil : Cxfxt Q T = L = Vg x Cp dxV Q = heating value of oil , K cal / kg C = Capacity of Kiln Ton / hr Vg = Volume of combustion gases , f = Ton (Kg) dry feed / Ton ( kg) of Clinker Nm^3 / Kg t = residence time Cp = Specific heat of d = Bulk density of dry feed ton (Kg) / m^3 combustion gases =0.40 at 2000*C for V = Internal volume of kiln in m^3 fuel class “S”

- 45. Rotary kiln Capacity Martin’s Formula : C = 2.826 v X D^3 Vg C = Kiln Capacity Ton / Hr V = Gas Velocity in gas discharge end , m / sec Vg = specific gas volume , m^3 / kg clinker D = Kiln Diameter on Bricks, m

- 46. Heat capacity of Rotary kiln 1 Q = 1.1 x 10 ^ 6 x D ^3 (Kcal / hr) D = Mean inside Kiln Diameter on Bricks, m 2 Kiln Thermal loading at cross section of burning zone = Qp = = Q / Fp Fp = 0.785 x D^2 Inside cross-section of the kiln burning zone m^2 where D is kiln shell diameter Q p = 1.4 x 10 ^ 6 x D Kcal / m^2.hr Qp should not exceed 3.46 x 10 ^ 6 kcal / m2.hr

- 47. Heat transfer in cyclones preheater: The rule is that the sizes of the gas ducts and of the cyclone should be in accordance with the formula: V^2 = Constant ID ^ 5 V = Gas volume ID = Inside Diameter of ducts / cyclones respectively

- 48. Preheater cyclone sizing (V) ^ 2 x Vt C D = 0.536 4 P Vt = V0 273 + t + K K = dust concentration in Gas , grams / m^ 3 273 D = cyclone Diameter , m V = Gas volume passimg cyclone , m ^ 3 / Sec Vt = sp. gr. of gas at aver. Temp , Kg / m ^ 3 C = Coefficient for pressure drop = 110 P = Pressure drop in cyclone in mm WG

- 49. Small size high efficiency cyclone L H 70 * L=H/2 Length of Dip Tube = ½ Gas inlet height Single Stream Pressure drop across cyclone = 55 – 60 mbar

- 50. Theoretical Heat consumption Q for clinker burning :zur Strassen formula : Constituent Constituent Multiplication Heat Cons Net Name X % Factor Y kcal/kg Al2O3 5.92 2.22 + 13.1 + MgO 1.05 6.48*MgO6.48 + 6.8 527.4 CaO 63.91 7.646 + 488.7 H2O 3.2 5.86 + 18.8 _ SiO2 22.68 5.11 _ 117 118.4 Fe2O3 2.31 0.59 _ 1.4 Net % 99.27 Net Kcal / Kg = 409.0 Q = 2.22 Al203 + 6.48 MgO + 7.646 CaO + 5.86 H2O + 5.11 SiO2 + 0.59 Fe2O3

- 51. Thermal efficiency of cooler = E A-B X 100 E= A A = Heat loss of clinker leaving the kiln B = Heat loss of the clinker cooler 3250 (347 – K ) Secondary Air Temperature = t = (X.n) K = Heat loss of the cooler , Kcal/Kg clinker X = Specific Heat consumption of the kiln , Kcal / Kg clinker n = Excess Air number = 1.1 Cooler fans designed for Specific Volume of 3 – 3.15 st.m^3/Kg clinker

- 52. Cooling of kiln Exit Gases (GCT) Kg / min.Exit gas x 0.25 ( t 1 – t 2) Kcal / min Y= H t2 – H t3 t1 = Temperature of Kiln exit gases t2 = Temperature of gas to be achieved or maitained t3 = temperature of water (15*C) H t2 = Heat content of water at t2 H t3 = Heat content of water at t3 Y = Kg Water Spray / min