1000 Ton Transfer Press Risk Assessment

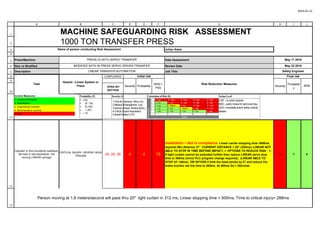

- 1. 2019-01-21 1 2 3 4 5 6 7 8 9 10 11 12 13 A B C D E F G H I J MACHINE SAFEGUARDING RISK ASSESSMENT 1000 TON TRANSFER PRESS Julian Kalac Press/Machine: Date Assessment New or Modified Review Date Description Job Title: COMPLIANCE OHSA 851 SECTION Operator or third accidently walkback, fall back or slip backwards into moving LIINEAR carriage CRITICAL INJURY- SEVERE HEAD TRAUMA 24, 25, 28 4 4 16 Installation – Not in compliance: Linear carrier stopping time =600ms, requires Min.distance 31" CURRENT DISTANCE = 20" (320ms)--LINEAR NOT ABLE TO STOP IN TIME BEFORE IMPACT--> OPTIONS TO REDUCE RISK : 1- If light curtain cannot be extended further then reduce LINEAR servo stop time to 300ms (minor PLC program change required), (LINEAR ABLE TO STOP AT 140ms) OR OPTION 2 limit the head stroke by 5" and reduce the brake monitor set trip time to 400ms. At 400ms Ds = 25inches 4 1 4 May 17 2018 May 22 2018 Safety Engineer Name of person conducting Risk Assessment PRESS 23 WITH SERVO TRANSFER MODIFIED WITH IN PRESS SERVO DRIVEN TRANSFER LINEAR TRANSFER AUTOMATION Probabilit y Task Hazard --Linear System or Press Initial risk Risk Reduction Measures Final risk Severity Probability RPN RPN = PXS Severity Person moving at 1.6 meters/second will pass thru 20" light curtain in 312 ms, Linear stopping time = 500ms, Time to critical injury= 288ms Control Measures 1. Hazard elimination 2. Substitution 3. Engineering controls 4. Administrative controls 5. PPE 20 – High 16 – High 12 – High 8 – High 4 – Low 4 Probability (P) Severity (S) Calculation of Risk (R) Action Level 1 2 3 5 20 - High 3 3 – Low 6 - Medium 9 - High 15 – High 2 2 – Low 4 - Low 6 - Medium 10 – High Severity 5 >75% 4 50 - 75% 3 25- 50% 2 1- 25% 1 < 1% Probability 5 5 – High 10 – High 15 – High 25 - High LOW – no action required MED – justify /review for each event day HIGH –immediate action/ further controls needed 4 4 – Low 8 – High 12 – High 1 1 – Low 2 – Low 3 – Low 5 – High 1-First Aid Abrasion, Minor Cut, 2-Medical (Entanglement, Cut), 3-Serious (Impact -Broken Bone,), 4-Critical (Guard-Amputation) 5-Death/Fatality-LOTO

- 2. 2019-01-21 14 15 16 17 18 19 20 21 A B C D E F G H I J 2 OR MORE OPERATORS , ACCIDENTAL RESET RESTART , OPERATORS CANNOT SEE OTHER SIDE CRITICAL INJURY, DEATH 24, 25, 28 4 4 16 HORIZONTAL LIGHT CURTAIN INSIDE DANGER ZONE CONTINUOUS DETECTION DUAL CHANNEL INTERLOCKED AND MANUAL RESET TIED TO SAFETY CIRCUIT LMC inputs 4 1 4 2 OR MORE OPERATORS , OPERAT FORGETS TO LOCKOUT, NO TAGS USED CRITICAL INJURY, DEATH 24, 25, 28 4 4 16 LOCKOUT TAG OUT PROCEDURE, LOCK /TAG MUST BE PLACED ON DIE HOLDING BLOCK PLUG WHEN INSIDE DIE AREA 4 1 4 NOT COMPLIANT WITH OHSA COMPLIANCE 27, CSA Z432 N/A N/A N/A It is suggested that the existing pushbuttons for “immediate stop” be replaced with self-latching button type that requires a deliberate pull-to-release or twist-to-release action, in order to provide further protection against accidental restar N/A N/A N/A PRESS ESTOP NOT HARD WIRED , does not stop motor/flywheel, does not override faults, does not prevent restarting and does not comply with mandatory OHSA and CSA requirements IF BRAKES FAIL OR PRESS MOTOR OR LINEAR CONTROLS FAIL TO STOP -- CRUSHED, AMPUTATION , ELECTRICAL SHOCK 27 3 3 12 STRONGLY RECOMMEND HARD WIRING E-STOP TO MAIN MOTOR PRESS . ENSURE FLYWHEEL IS DISENGAGED FROM MOTOR, constituting a non- compliance as per section 5 AND 8 OF CS Z432-04 3 1 3 Estops DO NOT PREVENT RESTARTING EQUIPMENT, NO RELEASE OF ENERGY AMPUTATION CRUSHING--IF STOP CYCLE FAILS TO STOP 27 4 2 8 It is recommended that the cycle stop buttons be replaced with yellow buttons to not be mistaken for emergency 4 1 4 E-STOP SOFT STOP CRUSHED, AMPUTATION , ELECTRICAL SHOCK 27,74,75, 4 2 8 STRONGLY RECOMMEND HARD WIRING E-STOP TO OVERRIDE ALL OTHER M,ACHINE CONTROLS AS REQUIRED BY CSA Z432 -04 SECTION 7.17.1.1 4 1 4 LINEAR TRANSFER 480 V NOT INTERLOCKED WITH DIE RAM BLOCKS DURING PRESS LOCK OUT-- LIVE WIRE ARC FLASH , ELECTRIC SHOCK DEATH 42, 43, 75 AND 76 5 3 15 MUST LOCK OUT HIGH VOLTAGE POWER WHEN PRESS LOCKED OUT. DEVELOP SAFE WORK PROCEDURE FOR PROPER POWER DOWN 480V 5 2 10 NO LOCK OUT PROCEDURE FROM LINEAR ON PRESS 39 OR 23 FROM LINEAR ARC FLASH , ELECTRIC SHOCK DEATH 42, 43, 75 AND 76 5 3 15 NEED LOCK OUT POINTS IDENTIFIED ON LINEAR AND RECOVERY FROM EMERGENCY STOP PROCEDURE 5 1 5

- 3. 2019-01-21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 A B C D E F G H I J RUNAWAY SERVO MOTOR LINEAR TRANSFER -- OVERRUNING IMPACT UNCONTROLLED MOTION 75 76 3 3 9 safe torque off function AND SAFE BRAKE CONTROL MUST BE PROGRAMMED INTO CODE 3 1 3 Starting and operation of equipment in any mode Entanglement and pinch point hazards at flywheel, motor, drive, and crankshaft 42 REG 851 3 3 9 42. (1) The power supply to electrical installations, equipment or conductors shall be disconnected, locked out of service and tagged before any work is done, and while it is being done 3 1 3 ALL TASKS Slip/trip/fall from oily surface near linear robot 25 (b) be located within easy reach of the operator. R.R.O. 1990, Reg. 851, s. 27. Current Press Controls are control reliable, light curtain fault prevents press from restarting . Linear to verify control reliable Stopping time of Linear needed for light curtain distance Improper shut down of electrical power Electric shock , Arc flash 42 , 75 76 3 2 9 Need to develop proper LOTO , identify authorized maintenance and train them on proper LOTO 3 1 3 Linear Lock-out procedure Interlocked access doors into feed area Interlocked light curtain into press tooling area Deliberate restart from outside safeguarded space Improper shut down of electrical power ELECTRIC SHOCK ARC FLASH HIGH VOLTAGE 25, 26, 75 & 76, 42 4 3 12 Need to develop proper LOTO , identify authorized maintenance and train them on proper LOTO 4 1 3 Crushed Arm/hand in die area 25 Light Curtain with Fixed side guard or double sided liught curtain Release of stored air energy in jammed pneumatic mechanism 75,76 Linear to ensure Electronic air dump when emergency stop actuated. 3 1 11 4 4 Slip Resistant PPE, Administrative Controls: Spill clean kits, SOP oil spills must be cleaned up immediately to porevent injury 1 25, 26, 75 & 76 75,76 1 4 Maintenance/Tool Maker entering inside die Crushed struck or pinched by any moving parts 4 3 12 4 1 2 Linear and Die Clear jam-up 4 4 16 4 Protection of personnel entering the equipment to perform maintenance FULL LOCK OUT TAG OUT REQURIED FOR ANY MAINTENANCE WORK 1 3 Clearing jam-ups, minor die adjustment Struck, pinned, or pinched by Linear Transfer tooling during normal operation 3 2 6

- 4. 2019-01-21 37 38 39 40 41 42 43 44 45 46 4748 49 50 51 52 53 54 A B C D E F G H I J Maintenance Clearing jam-up Gravity fall of pneumatic tooling or other components 75,76 1 1 1 Stroke and weight of tooling and workpieces is not considered to present significant risk of injury. Crushing hazard in die area 75,76 – powered motion – excluding “Inch” mode 75,76 Scrap removal Maintenance Crushing hazard in die area 75,76 Full LOTO main motor disconnect Automatic brake/restraint; counterbalance system; ram blocking Linear Tool changing and set-up Threading feed material Clearing jam-up – Falling by gravity when not powered 75,76 Residual risk is associated with ram blocking because there is no technically feasible method of enforcing its use. Training in machine operating procedures, machine entry procedures, lock- out procedures, and warning signs are feasible countermeasures. Maintenance Linear Tooling 75,76 Tool changing and set-up 75,76 Overload protection; arrangement of fixtures to accept only correct parts and only correctly oriented parts 27 Personal protective equipment must be used per Clause 14 of CSA Z142-10. Tooling must be designed to contain workpieces to the extent feasible. Since this machine can be used with different tooling, the on-going responsibility for appropriate tooling design to eliminate this hazard must lie with the tooling designer. 26 Sustained-contact manual control for “jog” of feeder in manual mode. The sustained- contact manual controls comply with CSA Z432-16 clause 7.21. Guides for the material are provided. 25, 26, 75 & 76, 42 Manual re-start required at end of roll from adjacent operator station with clear view of hazard area. Personal protective equipment must be used per Clause 14 of CSA Z142-10. Fixed guarding. 25, 26, 75 & 76, 42 Parts to be dropped into bin; further handling is outside the scope of this report. no action 3 1 3 3 1 3 Removal of finished parts Pinch points at parts take- away conveyor 3 3 9 All operating conditions in which strip is being used – when running- out the tail end of the coil End-of-coil “whipping” hazard 3 3 9 1 3 1 2 Threading roll-fed material through die at start of roll Pinch point between leading edge of feed material and die components; pinch points of die associated with necessary motions during 3 2 6 3 Loading or unloading parts improperly (double fed, improper parts loaded, proper parts loaded incorrectly) Tooling hazards – potential for ejecting workpieces or tooling in a hazardous manner 2 2 4 2 4 Crushing hazards associated with heavy tooling components or 4 2 8 Already in place Lift assist devices or Provide suitable means of lifting, and adequate clearance within and around the equipment 4 1 5 4 1 4 5 2 10 5 1 Scrap removal Maintenance Clearing jam-up 4 4 16 Lock out tag out procedure needs to be developed and ensure that the 480v disconnect is locked out and intelock ram blocks used to prevent stored energy from releasing. Full LOTO must be done during any maintenance